SHOULD LAMINATED PAPER GO IN THE RECYCLING BIN?

This question has likely been asked by anyone who wants to do their part to protect the planet while still reaping the benefits of paper packaging, such as folding cartons, paperboard containers, and holiday cards. While recycling may seem like a simple concept on the surface, the introduction of a plastic layer on a paper substrate immediately complicates things. After all, most bins clearly differentiate between paper and plastic products, so where does the eco-conscious consumer put an item that contains both materials?

A cursory search about the recyclability of laminated paper structures will show a long list of sources claiming these items should never be placed in the recycling stream. However, much of this information is outdated or otherwise inapplicable to the vast majority of laminated paper-based structures we come into contact with every day. As a lamination supplier concerned with doing what we can to be good stewards of the planet, Nobelus is committed to correcting some of the misconceptions surrounding recyclability and explaining why lamination may not inherently prevent already recyclable paper fiber from being accepted and processed in a recycling facility. Let’s take a closer look at what happens when a laminated paper product is placed in the recycling bin.

A QUICK DISCLAIMER

While we hope to serve as a helpful resource in understanding the possibilities and limitations of recycling laminated paper, Nobelus can make no definitive claims about the recyclability of any given material, structure, or package for several reasons. First, even the simplest laminated paper structure is composed of several different layers and material types, with the laminate typically serving as the final (and oftentimes thinnest) layer. Because Nobelus is not involved in the manufacturing process for these structures, we can make no claims about how the overall construction of the piece will affect its recyclability.

The information presented in this article assumes that a laminated structure is otherwise considered recyclable in a paper recycling stream. Additionally, different regions and paper mills will have varying standards, processes, and technological capabilities that may affect the end result of placing any given item in a recycling bin. The information shared within this blog should not be used for certification or labelling purposes.

Prime labels and flexible packaging, such as chip bags, candy bar wrappers, and toothpaste tubes, are fundamentally different than the paper-based items and packaging discussed in this blog post and should be evaluated separately.

THE PURPOSE OF LAMINATION

Before we focus on the recycling process, we need to understand why laminates are used in the first place. As a lamination supplier, Nobelus acknowledges that most laminates are made of plastic and that this plastic layer itself is not currently recyclable once applied, even though it may not prevent an otherwise recyclable paper product from yielding useful materials. While recycling laminated paper is extremely important, it is not the only factor to consider when evaluating the sustainability of lamination as a process.

Without a laminate layer, products are at high risk of being destroyed by dirt, moisture, and other contaminates before they ever make it to a store shelf or the end consumer’s home. Additionally, laminates enable products such as menus, loyalty cards, and board game pieces to withstand regular, repeated use, reducing waste through higher durability. True sustainability requires packaging producers to evaluate not only materials but also the function and design of a package to ensure the end result can fulfill its intended purpose.

ESTABLISHING DEFINITIONS

No conversation concerning sustainability can be truly helpful unless we first explain what’s being discussed. Terminology surrounding sustainability is oftentimes confusing and complex, so we will simplify a few concepts specifically for this discussion. Suppliers, brands, and recyclers should begin any conversation about sustainability by making sure they are aligned on how they are using these terms.

Recyclable

According to How2Recycle, a leading organization in recyclability labelling, “Packaging is recyclable if it can be collected, sorted, reprocessed, and ultimately reused in manufacturing or making another item… A package is recyclable only if there is a substantial likelihood that it can do all of those things in the majority of communities where an item is sold.” Under this definition, a recyclable product does not have to be reusable in totality; inefficiencies in the recycling process and impurities in feedstock rarely allow for the entire structure to be recovered and reprocessed into new material.

Repulping

Repulping (or pulping) is the process of transforming a paper product into individual paper fibers by blending it in water and chemicals. Through this process, the fibers expand and separate from other parts of the structure and can go on to be cleansed from other impurities before being reprocessed into new material. This is the first major step in the recovering process for paper products.

Paper Fibers

These tiny fibers usually make up the larger portion of a paper structure and must be separated from each other and impurities before they can be reused in other paper products. These fibers are what recyclers are trying to glean from paper items placed in a bin.

Impurities | Contaminates

Because recovering fibers to be reused in other applications is the end goal of recycling paper, other materials in a paper structure are considered impurities or contaminates. This can include additives, fillers, paper whiteners, ink, coatings, waxes, foils, metals, and laminates. Even blank copy paper will contain impurities that prevent a 100% yield.

Fines

Fines are paper fiber that is too small to be captured as recovered fiber and recirculated back into the paper-making process. While this material may not be useable for recycled paper product, it is often still redirected to other uses, such as animal bedding or seed encapsulation.

Materials Recovery Facility (MRF)

These plants accept, sort, organize, and bale materials to be sent to manufacturers. The technological capabilities and mechanical processes each MRF uses can vary. For instance, some MRFs will shred materials, while others do not have the equipment to do so.

Pulp Mill | Paper Mill

A pulp or paper mill is a company that selects and purchases baled paper material from MRFs to pulp it and produce recovered fiber. Some of these mills focus on producing fiber that will be sent to other mills for paper production. Others pulp the material, produce paper fibers, and manufacture new paper products within the same organization.

Lamination

In this context, lamination is the process of combining a paper substrate with a thin protective layer, oftentimes (but not always) made of plastic. A film becomes a laminate when another layer of material, such as an adhesive layer, is added to it to support application or function. Films (laminates without adhesive) follow the same paths as laminates through the paper recycling process.

Encapsulation

When a piece of paper is completely enclosed between two pieces of laminate with sealed edges, it is called encapsulation. This type of lamination is traditionally used only on applications requiring very thick laminate or water protection, such as menus or reusable educational tools. Most paper packaging, such as folded cartons, are laminated on one side only or else cut to leave the edges of the paper substrate exposed.

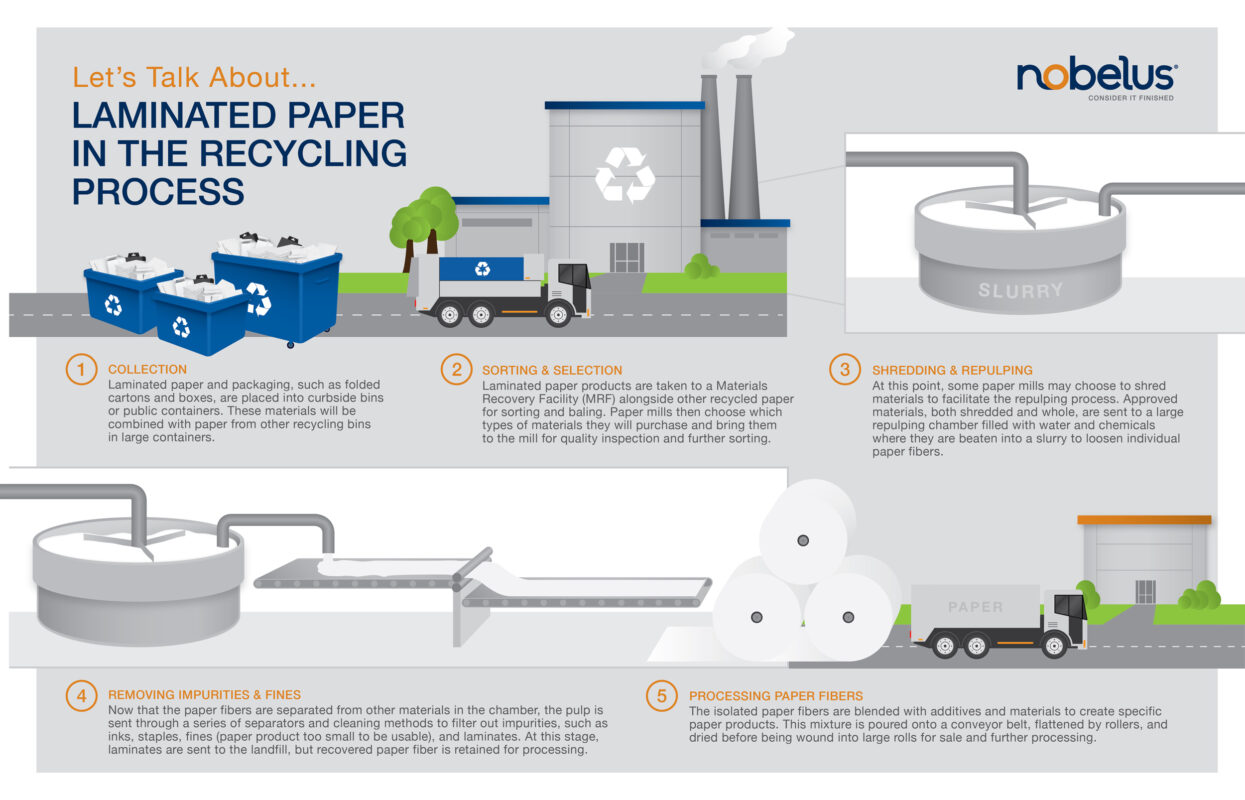

THE PAPER RECYCLING PROCESS

While the details of the recycling process may vary slightly between different MRFs and paper mills, most recycled paper will go through the same basic process. Let’s take a closer look at what happens when a laminated paper product is placed in the recycling bin.

COLLECTION

A laminated paper product first enters the recycling stream via bin, container, or other deposit method. Individual consumers who are asked to perform the initial material sorting themselves (common with public bins and certain pickup services) should always place laminated paper in the container labeled for paper unless otherwise noted on the container itself.

SORTING & SELECTION

The laminated paper is transported to an MRF alongside other paper products to be sorted and baled according to product type. After the paper is baled, paper mills then choose which materials they would like to purchase and recover based on their processing capabilities and market price. Once the product has been transported to the paper mill, recyclers will perform a quality inspection on these materials once again to ensure they can be processed. Certain products may be rejected for a variety of reasons, from equipment limitations to quality requirements for the final paper product.

Based on conversations Nobelus has had with testing facilities and recyclers, many recyclers are currently encouraging consumers to send in all laminated paper products and trust the professionals to make the final decision. Paper that is deemed unsuitable for recycling may be sent to either a landfill or another recycling center that accepts lower quality materials for products such as craft paper or recycled tissue.

SHREDDING & REPULPING

Once product has been approved through inspection, paper material may then go on to be shredded, depending on recycler preference, ability, and the material they are processing. The selected paper materials, whether shredded or whole, are then added into large repulping chambers along with water and various chemicals that facilitate the separation process. The resulting slurry is then stiffly beaten, loosening the individual paper fibers and other layers in the structure.

When someone claims laminated paper cannot be recycled, this stage is likely to be their key concern. Many people believe the moisture-resistant laminate layer will prevent paper from soaking properly. However, repulping technology has tremendously advanced over time, and modern variations generate an impressive amount of power and abrasion to ensure these fibers release. In turn, most modern repulpers are able to separate paper fiber from many types of materials.

While encapsulated products do prevent water from reaching the paper in their original state, many facilities will choose to grind this product before it is added to the pulper, exposing the paper to water. If the recycler does not have the equipment to perform this step and it was not shredded at the MRF, the encapsulated paper will be removed in the sorting stage.

REMOVING IMPURITIES & FINES

Once the pulp has been beaten sufficiently and the paper fibers separate from the other materials in the chamber, impurities such as ink, staples, glues, laminates, and fines (paper product too small to be considered useable paper fiber) are filtered out through a series of screens, floatation separators, and other highly sophisticated cleaning methods. These impurities are then sent to the landfill or set aside for other uses, such as animal bedding, seed encapsulation, or molded fiber. At this time, laminates separated from their paper substrates in the recycling process are not recycled in any known facility and will be sent to the landfill. However, processes and technologies that would enable these plastics to be reused are currently being researched.

PROCESSING PAPER FIBERS

Now that the useable paper fibers have been isolated, they are blended with additives and materials to achieve the right composition for a specific paper product, such as newspaper or office paper. This step may occur at the facility that pulped the product, or it may happen after the paper fibers have been shipped to another location. The carefully crafted mixture is poured onto a conveyer belt and flattened into a long sheet by rollers. These sheets are dried before being wound into huge rolls that will be cut and sold to paper distributors for further processing and sale.

LIMITATIONS & TESTING

Given that laminated paper is accepted and processed by many recycling centers every day, why has the idea that laminated paper cannot be recycled become so pervasive? The issue stems from an oversimplification of the recycling process, outdated testing procedures, and massive differences in recycling capabilities across regions. Most people want a clear binary answer about whether or not the product they drop in a recycling bin will ultimately be repurposed, but with millions of paper product permutations and thousands of MRFs and paper mills in the United States alone, it is impossible to make blanket statements that will prove true for every paper product.

Currently, no single certification or test accurately represents paper recycling capabilities today for processing laminated paper. While some tests may be cited as an authoritative source, under closer observation, these tests prove to be outdated and misapplied to other applications and processes than what the testing protocol was written for. Oftentimes, these tests have higher standards for yield percentage than the average recycler requires and are limited in scope by the capabilities of the facility used to conduct the tests. Eco-conscious brands will get more accurate information by personally reaching out to a variety of recyclers in regions where their product will be used to gain a more comprehensive understanding of what products will be recycled in different contexts.

While no accurate standards exist today for recyclability of laminated paperboard, tests do exist to give recyclers an accurate idea of whether laminate will separated in processing, freeing paper fiber to be recycled. Through testing and conversations with recyclers, we are confident that technology capable of recovering useable fiber from laminated structures with ease is being used in the market today.

CURIOUS ABOUT LAMINATION AND SUSTAINABILITY?

If you are a brand owner or printer who wants a better grasp on how lamination can fit into an eco-conscious packaging model, give us a call or contact us on our website. Our solutions experts and customer representatives are ready to answer any questions you may have and help you find the best solutions for your unique needs. Be sure to ask about our EcoElement™ CLS Laminate, which is made of sustainably sourced cellulose and provides an excellent way to reduce plastic usage on packaging while protecting designs.