PULLING BACK THE LAYERS OF THERMAL LAMINATING FILMS

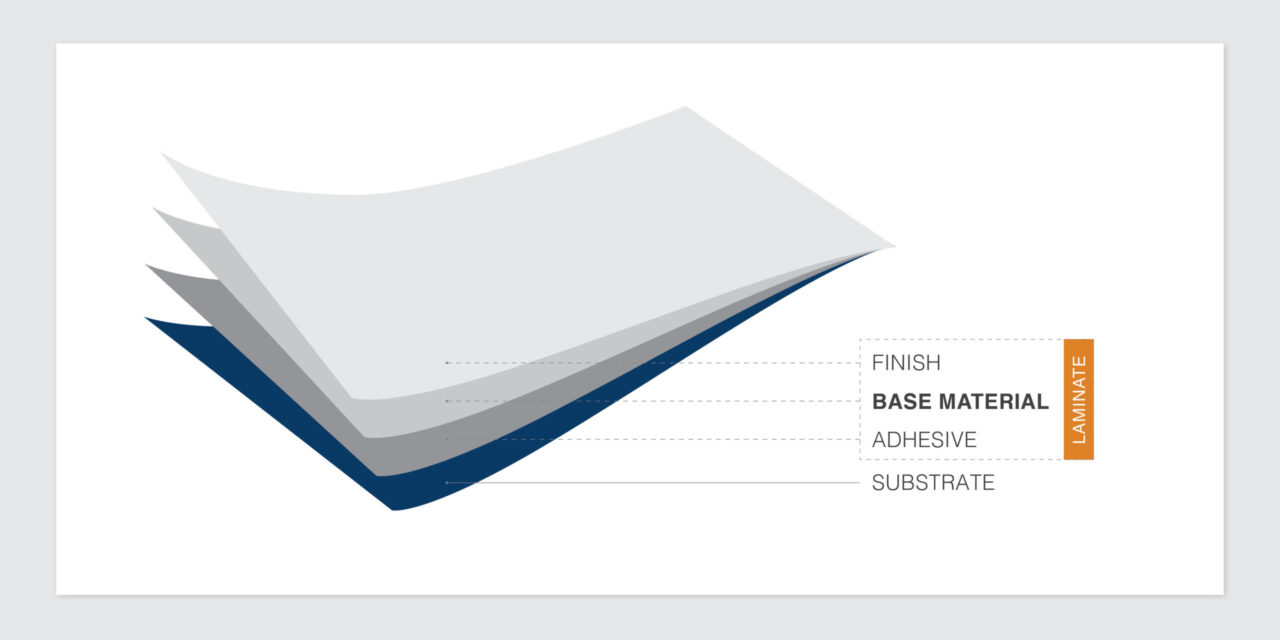

While laminated pieces may seem simple on the surface, they are actually complex structures made up of several thin, distinct layers. Substrate, ink, adhesive, laminate, and various other elements work together to add value to a package or printed piece. Printers have to make a host of decisions about a range of materials to ensure the finished product comes together in just the right way. Each layer brings with it its own list of questions, and lamination is no exception. Which finish is best for the specific application? What adhesive will work best? How much will the laminate’s thickness affect the end product?

Today, we’ll be taking a look at one of the most essential layers in lamination: the base material. While they may differ in thickness, finish, and adhesive type (or lack thereof), every thermal laminate and unsupported film has a base material that serves as the starting point in the manufacturing process. A laminate’s base material influences its cost, equipment and application compatibility, receptiveness to post-laminate processes, and much more.

BASE MATERIALS IN THE NOBELUS PORTFOLIO

Nobelus offers thermal laminates and unsupported films in four different base materials. While the following information is accurate broadscale, there may be instances where the introduction of other layers, processes, or materials affects the validity of these claims. As always, we highly recommend printers perform a trial run for each new application to guarantee the finished product meets the printer’s standards and functions as intended.

BOPP (POLYPROPYLENE)

Short for biaxially oriented polypropylene, BOPP (or OPP) is typically the easiest base material to process in a single-sided laminator due to its inherent softness. During the manufacturing process, BOPP is stretched in two directions, making it highly malleable and easy to manipulate. Of all the laminate bases, this type is the most receptive to post-laminate embellishments, which can include anything from folding and die cutting to embossing, although the finish it is paired with will have an effect on which processes it can receive, especially when stamping or liquid coatings are used. BOPP laminates in the Nobelus portfolio come in a range of finishes, from basics such as gloss and matte to premium soft-touch and rugged rough-touch.

High-volume commercial laminating facilities primarily use BOPP because of its machineability and the fact that it is by far the best base material to use for bursting separation, enabling affordable, efficient lamination. BOPP is best suited for single-sided applications and should not be used to encapsulate a sheet because of its softness. Applications that need added rigidity and thickness will need a different base material than BOPP. Most other applications, including brochures, business cards, prime labels, and sachets, will benefit greatly from BOPP’s ability to protect designs and packaging from grease, oil, and dirt while providing some aesthetic appeal depending on the laminate’s finish.

PET (POLYESTER)

PET, or polyethylene terephthalate, is the most common polymer resin in the polyester family and is therefore often referred to simply as polyester. PET laminates in the Nobelus catalog come in the widest range of thicknesses – 0.8 to 10 mil – making them suitable for a wide range of applications, from folding cartons and menus to identification cards and signage. PET is very rigid and will inherently add durability to a printed piece without making it brittle, resulting in tough products with just enough flexibility to prevent snapping or breaking when bent. However, this same durability means PET is less receptive to certain post-lamination processes, such as embossing, but gluing, stamping, and spot UV may see success if the product has been given an additional coating to increase its receptiveness. All PET laminates can be die cut, and they are suitable for encapsulating a printed piece to provide an extra level of protection.

Because thicker laminates run the risk of curling when applied to only one side of a thinner substrate, PET laminates with a thickness of 3 mil or higher should be used for double-sided lamination only and must be matched with laminates of a similar thickness. This helps ensure the finished piece will lie flat without bowing or canoeing after it cools. While PET is wonderful for many applications, it typically has stricter equipment requirements. This base material is generally not compatible with bursting separation and instead must be used on a laminator with a flying knife, hot knife, or other slicing separator. Printers who choose a thermal laminating film made of PET should always verify that its unique characteristics are the best fit for their specific application. This material is available in gloss and matte in addition to specialty finishes, such as a spectral holographic pattern and a velvety soft-touch.

NYLON

Nylon laminates are almost always used on single-sided book covers to prevent them from curling away from the pages as time passes. While other plastics may block out ambient moisture, nylon is hygroscopic, which means it lets water pass through and is essentially unaffected by humid environments. This helps keep products laminated with nylon from bowing or otherwise changing their shape. Nylon laminates are excellent for preserving a book cover’s visual elements in transit from the printing facility to store or library shelves, where it will continue to protect the book as it sees high volumes of handling and bending.

Because nylon is one of the more expensive laminate materials, we recommend using it for applications that will benefit most from its unique properties. It reliably accepts die cutting and spot UV, but other post-lamination processes may prove compatible when tested in trial runs. While it is possible to burst nylon, this material is best suited for single-sided laminators that utilize a flying knife, hot knife, or other form of separation besides bursting. In some instances, nylon can be suitable for encapsulation.

CLS (CELLULOSE)

A more recent addition to the Nobelus portfolio, CLS (also called CELLO) stands for cellulose, a plastic-free, bio-based material. CLS laminates are manufactured with 20-25% reprocessed cellulose film and PEFC-certified wood pulp, a certification that guarantees sustainable sourcing practices. Currently, Nobelus offers four distinct products that use CLS as a base: EcoElement CLS Gloss/Matte Laminate and EcoElement CLS Gloss/Matte Film. While the base material used in CLS thermal laminating film is plastic free and certified compostable, the addition of an EVA adhesive layer prevents the laminate as a whole from being classified as compostable. However, CLS unsupported films have no adhesive layer and therefore are completely compostable in home and industrial settings when combined with other compostable materials, making eco-conscious prime labels and flexible packaging feasible.

Even with the addition of a plastic-based adhesive, CLS laminates can reduce plastic usage in print and packaging for a variety of applications, including business cards, direct mail, folding cartons, and point of sale pieces. It is especially beneficial for applications that need easy tear functionality, such as stick packs. This material is also compatible with a host of post-lamination processes, from die cutting and folding to embossing and offset, UV, and screen printing. Laminates and films with CLS as a base work best with paper-based substrates that can flex and stretch to accommodate changes in ambient conditions. Rolls of CLS are more fragile than other materials; they must be stored in a metalized bag on a suspended core when not in use and should never be stood on their ends.

INTERESTED IN A SAMPLE?

The best way to learn about thermal laminating films is to personally see them on a finished piece. Nobelus offers samples to all potential customers so you can make sure you know exactly which product you need to bring your prints and packaging to the next level. Each of the base materials listed in this article can be found in a range of finishes with different haptic and visual effects. Talk to one of our customer representatives to learn more about the Nobelus portfolio and explore your options.