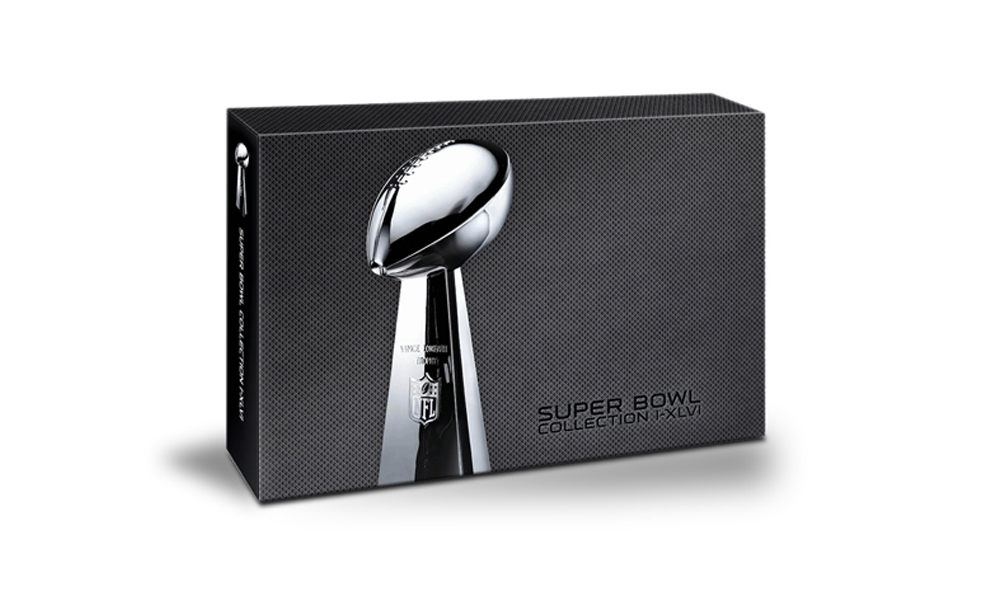

Many top brands now use laminates to create eye-grabbing packaging, blending tactile films and new finishing techniques to enthrall the consumer and better protect the finished carton

ATTRACT ATTENTION & INCREASE SALES

New finishing techniques and film laminates are allowing brands to create stunning tactile and visual effects. Designed to allure at the shelf, marketers are realizing the potential of special effects such as holography, simulated linen, soft-feeling films, Fresnel lens films, metalized surfaces and much more. Savvy companies are also learning that combining multiple effects on one package attracts even more attention. New effects also include engraved films, which simulate etched metal, as well as fine-grained leather films and strong anti-scuff films.

Many laminates today are also treated to accept other spot finishing or printing techniques such as spot UV coating, other laminate films, and foil stamping. These special effects deliver increased visual appeal to make high-end products stand apart from the competition, promoting a high-quality brand aesthetic while also offering distinct functionality and protection.

“The biggest thing is they attract the consumer’s eye – as 70% to 80% of purchasing decisions are made at the shelf, it’s critical to have your product stand out from your competitors’.”

Provide Increased Protection & Durability

Laminating folding cartons also adds several valuable physical benefits. The structural strength of the carton is increased, offering more protection for the product inside. The familiar cracking on the surface along folds (especially with digitally-printed cartons) is eliminated when a laminate is applied to the surface of the board.

Cartons can be laminated on the inside as well as the outside, for both aesthetic and physical purposes. As an example, metalized films can be used to deliver increased barrier protection from such things as odors and moisture exposure. In addition, the inherent thickness of laminate enables designers to spec a thinner board without compromising durability.

Perhaps one of the biggest uses of lamination today is scuff and scratch protection. Given that billions of packages produced in the East annually are transported up to 12,000 miles, many brands struggle with maintaining a quality surface on the outer folding carton. Burnishing, scratching and scuffing plague many beautiful folding cartons, ruining the desire by owners to maintain a premium exterior from source-point to final sale. A new generation of anti-scuff films, often available in various degrees of matte finish, is proving a superior match for these long-distance conditions.

Considering the advancement of special effects, the ever-increasing brand desire for a premium customer experience, and today’s short-run print technology, the growing popularity and appeal of laminated folding cartons will most certainly continue to increase.