THE IMPORTANCE OF FLEXIBLE PACKAGING STRUCTURES

In most print and packaging markets, including general commercial print, book covers, prime labels, and folding cartons, the appearance of the product’s exterior is the most crucial characteristic apart from general quality concerns. However, in flexible packaging, the structure and performance of the package are without a doubt the most important factors in its production.

Graphic design and eye-catching elements are certainly becoming a higher priority for most brands, but the layers that lie beneath the surface of the package are what make it a truly high-quality product. A well-designed flexible packaging structure can help keep food from going bad, extending its shelf life and preventing negative consumer experiences. In both inedible and edible applications, a flex pack structure should be able to keep powders from clumping, liquids from leaking, and ambient moisture from damaging more fragile product types.

Regardless of their experience level, every flexible packaging converter should have at least a passing knowledge of the different structures that could be important to the brands they serve. While not every converter needs to have perfect recall of every possible material combination, each should know about the properties and requirements of different niche applications as they apply to their business, such as cosmetic packaging, frozen goods, children’s products, caustic cleaning supplies, and other highly specific applications.

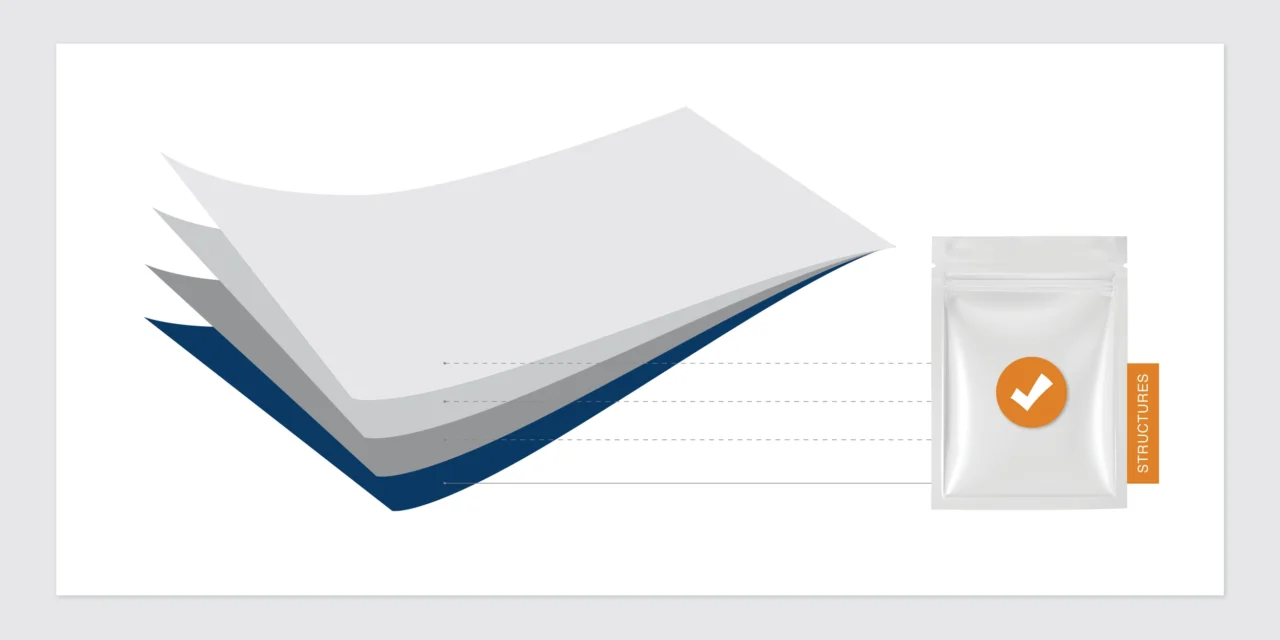

What Is a Packaging Structure?

In the flexible packaging industry, a “structure” is a flat web made up of several different layers. Sometimes each layer is made of a different material, but other times, many layers will be the same material. Two structures could be nearly identical, but even the smallest difference in a layer’s material type, thickness, or even adhesive could mean they are best suited for different purposes. These various structures can be shaped and formed into many different types of packaging, but it is ultimately the layers within each that dictate how they should be utilized as packaging.

While some flexible packaging has only one or two layers, most structures will include a seal layer that enables the package to be sealed shut, barrier layers that prevent oxygen, water, and other environmental factors from harming the product stored inside, a structural layer for packaging that needs to be more rigid, and finally a print layer, which can include anything from a printable film for designs to an overlaminate finish. The entire finished structure is held together with tie layers, or adhesive.

For more in-depth information about the basics of making a flexible packaging structure, take a look at our blog post, How Is Flexible Packaging Made?

COMMON STRUCTURES FOR DIFFERENT MARKETS

Different materials can take on specific properties when combined with other materials, which means a flexible packaging converter needs to know more than just the base properties of the films they use. They also need to understand how each material’s strengths can be enhanced by strategically pairing them with other layers. As we will see below, sometimes combining even two of the same film can improve performance compared to simply increasing the thickness of a single film web. To brush up on basic film material knowledge, read our blog post, Choosing Materials for Flexible Packaging.

The following structures are some of the most common options in the flexible packaging industry, although the markets and applications they are typically used in will vary. While many converters may choose to create these structures in-house, particularly if the converter utilizes solventless or solvent-based lamination, most of them are also available as pre-laminations from manufacturers. Whether you are new to the industry using a thermal laminator or have decades of experience with creating your own web in-house, the following structures will likely play a vital role in your business.

Metalized Polyester (METPET)

Perhaps one of the simplest structures, metalized polyester, or METPET, is exactly what its name implies: a polyester film with a metallic coating or metalized vapor. The type of metal used in the coating process can vary, but aluminum is the most common option. This structure combines the well-known durability and rigidity of PET with the moisture-, gas-, and UV-resistant properties of aluminum to create a web that will help prevent products from rusting, clumping, or going rancid.

METPET is used in a wide variety of applications and markets, including salty snacks (chips, nuts, etc.), coffee and tea, pet food, and non-food packaging such as medical supplies and cosmetics. In addition to protecting products, it can also serve an aesthetic purpose in markets where a metallic appearance can catch the consumer’s eye, such as cannabis pouches. METPET is also an excellent option for packaging that needs enhanced tensile strength and high resistance to water, such as granola bars that will be taken on the go for hiking or kayaking trips.

Metalized Polypropylene (METOPP)

Similar in many ways to METPET, metalized polypropylene, or METOPP is another plastic film with a metallic coating. Unlike METPET, METOPP is not known for its rigidity or durability, making it a better option for packaging that needs to be highly flexible. In general, OPP films are more cost effective than PET plastics, which means METOPP can also serve as a viable option for packaging applications that need some degree of resistance to moisture and gases while still meeting certain financial requirements.

Compared to aluminum foil web, METOPP provides higher resistance to punctures and tearing, which means it can serve as an affordable alternative for flexible packaging converters who want to utilize the properties of aluminum foil without the risk of a damaged package. Because OPP is so malleable, it reduces the likelihood that cracks will form in the aluminum layer as the package is bent and folded in production, shipping, or the hands of the consumer. This helps ensure the aluminum layer’s barrier properties are preserved throughout the life of the package, protecting products from the negative effects of moisture, gases, and UV light in the environment.

Cosmetic Web (Cosweb)

Short for “cosmetic web,” cosweb is a structure widely used for packaging in the cosmetics industry. A cosweb structure can vary in terms of material thickness and treatments, but every cosweb follows the same basic formula: a linear low-density polyethylene (LLDPE) sealant layer that keeps liquids, gels, and oils from escaping, an aluminum barrier layer that prevents the transmission of moisture and oxygen, a low-density polyethylene layer (LDPE), and finally a PET top layer that can be overprinted.

This combination of materials is crucial for many cosmetic applications due to its ability to form an airtight seal and keep the product from being contaminated or ruined by environmental factors. Additionally, many cosmetic products can include caustic, or harsh, chemicals. Cosweb helps ensure that these chemicals are kept inside the package until a consumer intentionally opens it to prevent damage to the consumer’s other belongings, such as purses or bags the package may be stored in.

Paper-Poly-Foil-Poly (PPFP)

Paper-poly-foil-poly, sometimes abbreviated to PPFP, is a structure composed of a LDPE seal layer, an aluminum barrier layer, another LDPE layer, and finally a paper exterior that is typically coated for added protection and overprinting. PPFP is ideal for packaging foods such as spices, soup mixes, seasonings, and other products that have been dehydrated. Once again, the aluminum layer provides superior resistance to moisture and humidity, keeping the product from clumping together, molding, or absorbing unsavory odors from its surroundings.

This structure can be seen across many food aisles in a typical grocery store as it is ideal for both small or individual packaging, such as instant dry yeast, and larger packaging with products made to serve a group, such as instant mashed potatoes or soup mixes. The exterior paper layer serves an important function not just for marketing purposes but also in blocking UV light from entering the package. While PPFP is commonly found in sachet formats, it is also a popular substrate for box-gusseted bags and some stand-up pouches.

70/70

Nearly everyone who has eaten a candy bar has encountered 70/70 film in their daily life, and it is common in many other types of packaging, as well. This deceptively simple structure is made up of two layers, each composed of 70-gauge OPP. Like other OPP structures, 70/70 is highly malleable and helps reduce material costs. However, one question may immediately come to mind: Why would a converter not just use a single 140-gauge OPP instead of combining two thinner films?

70/70 film is a perfect example of how combining two film layers – even two identical film layers – can significantly alter the properties and performance of a structure compared to using a single layer. With a single 140-gauge film construction, the design must be printed either on the inside of the wrapper, which needs to serve as the seal layer, or on the outside of the wrapper, resulting in a high risk of scuffing and smudging. In the case of 70/70 structures, adding a second identical layer provides the converter with two more surfaces that can be used as a seal surface and a print surface, leaving the outer film as a protective layer overtop the ink to prevent designs from being marred as the package moves from location to location.

Many other structures use similar compositions with films other than OPP to achieve better performance as, much like building blocks, films take on new properties and strengths when combined with other films. Learning how to strategically combine different layers to optimize the performance of the final package is a crucial skill for any flexible packaging converter who wants to create their own structures in-house.

WANT TO LEARN MORE?

If you want to learn more about the structures covered above or would like to explore other structures relevant to the markets you serve, don’t hesitate to reach out to our team by phone or email. Our in-house solutions experts have cumulative decades of experience with all things flexible packaging, including application engineering, material selection, food safety, and more. We can help you reach your flexible packaging goals and provide you with a host of premium print web films that will wow brands and consumers alike. Gain access to dedicated support and a diverse range of specialty finishes by contacting our team today.