CREATE UNFORGETTABLE SPECIALTY LABELS FOR ANY MARKET

Boutique brands are bigger than ever, and the average number of SKUs on store shelves continues to grow. In a time when brands are constantly competing for the attention of consumers, it is more important than ever before to stand out at a glance. Specialty labels are a cost-effective way to help smaller brands and niche product lines catch the eye of passersby.

While premium finishes such as a soft-touch feel, holographic pattern, or rough sandpaper texture play a crucial part in making unique labels, post-laminate embellishments remain a widely untapped treasure trove of creativity. This article will look at a variety of embellishment technologies that give labels an extra pop on the shelf and highlight some label films that are compatible with these value-add processes.

EMBELLISHMENT TECHNOLOGIES FOR UNIQUE LABELS

Specialty labels need more than bright inks and eye-catching designs. Embellishments provide a striking contrast for the most important elements in a label’s graphics, giving them added dimension and greater impact. The more embellishments a converter offers brands, the more flexibility and creativity the brand can express through the partnership. Below are some of the most common embellishment technologies:

Die Cutting – While most embellishments involve adding elements to a label, die cutting instead removes material. By cutting the edges or interior of a label, designers can form creative shapes and cutouts that complement graphic designs. Most label films are compatible with die cutting.

Spot Foiling – Spot foiling can be achieved through either hot or cold foiling. Hot foiling utilizes heated metal dies to activate the thin adhesive layer on a foil film and press a design onto the surface of a specialty label. Cold foiling is performed by applying a pressure-sensitive liquid adhesive to a label before foil is pressed overtop and peeled away. In both cases, it is important that the surface of the label forms a strong bond with the adhesive to ensure the effect lasts. To learn more about foiling, read our article “Hot Foiling vs Cold Foiling”.

Spot Varnish – Spot varnish is an advanced coating method where a clear liquid design is printed onto the surface of a label before being cured with UV light. The result is a clean, precise design that makes a label shine in specific areas. The effect is highly durable due to the UV curing process, enabling it to endure repeated handling as consumers look at the product.

Stamping – Similar to foiling in many ways, stamping transfers ink or foil to the surface of a label using high amounts of pressure. Stamping often leaves a slight indent in the label, leading to truly unique label designs that make use of texture and dimension.

FILMS FOR SPECIALTY LABEL EMBELLISHMENTS

Nobelus offers a variety of gloss, matte, and specialty films that are compatible with post-laminate embellishments. Converters can use tactile films like Karess® soft touch or FineGrit™ sandpaper to layer effects for one-of-a-kind designs or use more durable films like ScuffProof® to ensure labels have a long shelf life.

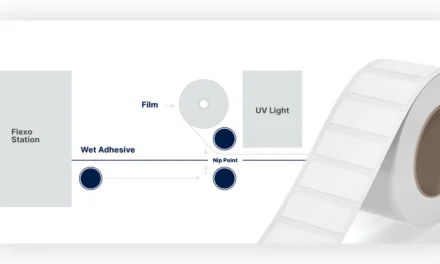

However, when it comes to embellishments, no film is better suited than our PlatinumOPP™ 48 ga Gloss/Matte Film, which is specially designed to accept UV ink, hot and cold foiling, stamping, and much more. This unsupported film is manufactured with a coating that makes it highly receptive to embellishments, something that is possible because it has no pressure-sensitive adhesive. All films in the Nobelus Prime Label portfolio are designed for wet lamination.

WANT TO LEARN MORE ABOUT SPECIALTY LABELS AND WET LAMINATION?

Read our article on wet lamination and its benefits here. If you would like to learn more about our prime label solutions, our experienced in-house solutions experts are always available for a call. Reach out to us by phone or email to get more information about wet lamination, specialty finishes, embellishments, workflow efficiency, and other industry-related topics. Our goal is to become a trusted supplier and partner to help your company achieve long-term success.