THE HISTORY OF PRINT AND PACKAGING

While the words “print” and “packaging” often go hand in hand today, the two concepts would not be combined for the sake of branding and marketing products until the 19th century. For most of human history, the craft of storing goods for transportation and preservation remained completely separate from the art of printing. Only as humanity became more adept at producing goods at an industrial scale did the need for printed packaging cause these two arts to converge. Let’s take a brief look at the history of print and packaging to gain a better understanding of their modern importance.

PACKAGING IN EARLY CIVILIZATION

Archeological findings indicate that packaging has played a vital role in the daily lives of humans since we first began using tools. Unlike today, where packaging typically is made of plastic or paper, ancient packaging was frequently made of leaves or wood, animal skins, and the hollowed-out shells of nuts and gourds. Before the development of agriculture enabled people to settle in a single location year-round, packaging played a crucial role in helping transport water, food, supplies, and other necessities.

The emergence of crops, animal husbandry, and more specialized skill sets encouraged trade between villagers and eventually different villages. As trading and bartering grew in prominence, so, too, did the use of packaging to carry goods over long distances and store them in homes for later use. Wooden boxes and casks, pottery, animal-skin bags, and other more advanced versions of basic packaging were developed to help goods last longer in harsher conditions.

THE INTRODUCTION OF WRITING SYSTEMS AND INK

Around 3100 BCE in modern-day Iraq, Cuniform emerged as the earliest recorded example of a writing system in human history, although there is evidence that different systems also developed independently in Mesoamerica and China around the same time. In these early years, symbols were typically etched or carved into solid surfaces using a stylus or knife. This method worked well for conveying simple information on jars and boxes, such as what items were inside, the name of the sender or recipient, or measurements to track inventory and dates. Much early writing centered around accounting and data records rather than story telling or advertising.

Although early cave paintings indicate that humans used soot, clay, and other materials to create pigments for their artwork well before the advent of agriculture, people would not develop ink and tools for writing until a couple of centuries later, with Egypt and China both serving as two of the first adopters. The invention of durable papers such as papyrus, parchment, and vellum enabled ancient societies to record and share complex information in compact scrolls.

THE EFFICIENCY OF THE PRINTED WORD

While ink continued to develop and see more widespread use across different civilizations, it would be the middle of the 10th century before the first Chinese printers would implement wood-block printing to create copies of popular classical books. A rudimentary form of relief printing, this method required symbols or images to be carved into wooden blocks in order to transfer ink to a page. Before this point, manuscripts were copied by hand; by using these wooden blocks, printers could copy texts with greater efficiency and consistency than ever before.

Over the next several centuries, similar technologies would gain traction in middle eastern and western societies as paper became more available. Wood blocks were adapted into metal plates that could transfer more information per press. By 1445, Johannes Gutenberg had created the first movable-type printing press in modern-day Mainz, Germany. His was far more complex, efficient, and economical than previous printing technologies, leading to a book boom as copies of texts could be reproduced at high volumes faster than ever before.

As books became more accessible to the public and literacy rates rose, a more educated population gradually gained the ability to interact with the world and other people in new ways. Newspapers, brochures, political pamphlets, and other newly penned texts were dispersed to a growing number of readers. Over the next few centuries, paper mills were established across the western world to meet a growing demand for printed materials. The invention of stereoplates in the early 1700s enabled printers to quickly set up additional runs of published type with short notice, a practice that became indispensable for the newspaper industry.

The first steam-powered cylindrical press was patented in 1811 by Frederich Koenig, but the rotary printing press that enables substrates to be fed in as a web would not be patented until nearly 1850. This design would eventually lead to the development of several different types of rotary printing methods that are still in use today, including offset lithography, rotogravure, and flexographic printing. While there is evidence that color prints had been produced since at least the Ming dynasty in China, it would be 1837 before Godefroy Engelmann would receive a patent for chromolithography.

THE ADVENT OF MODERN PRINTED PACKAGING

With the western world settled fully into the industrial age, food began to be produced on a much larger scale that enabled broader distribution of perishable goods through preservation processes such as canning and pasteurization. Farm-to-table meals became less commonplace as people moved to major cities for work, and packaging became more crucial than ever not only for transportation and storage but also for longevity and accessibility.

Flexography entered the industry around 1890 and provided an efficient means to print information and branding on food packaging. However, concerns about the safety of early aniline dyes and general struggles with printing quality meant most labels and food packaging would be printed using an offset press until the late 20th century. After much advancement in the realm of flexography, it began to play an indispensable role in the printing of labels, bags, wrappers, pouches, and other types of packaging in the 21st century to the present.

While offset printing is still used for most print-focused applications, such as books, business cards, and brochures, and many types of paper-based packaging, including folding cartons and rigid boxes, the development and proliferation of flexible plastic packaging throughout the 20th century has allowed flexographic printing to become a leading technology in the industry.

In 1993, at the dawn of the information age, Benny Landa introduced the first Indigo digital color press and spurred a revolution in print. This innovative printing technology did away with the concept of printing plates entirely and made it possible to print directly onto paper and other substrates. The development of electro-ink enabled printers to replicate colorful, complex designs by placing tiny particles of cyan, magenta, yellow, and black with incredible accuracy.

By the 1990s, Indigo became a significant alternative to traditional offset presses. Modern-day tech giant Hewlett-Packard invested $100 million into Indigo digital technology in 2000, buying the remainder for $629 million a year later. Over the following decades, digital printing competitors emerged with their own unique solutions, resulting in a more robust landscape as manufacturers race to consistently upgrade their machines with incredible quality and efficiency improvements.

PRINT AND PACKAGING TODAY

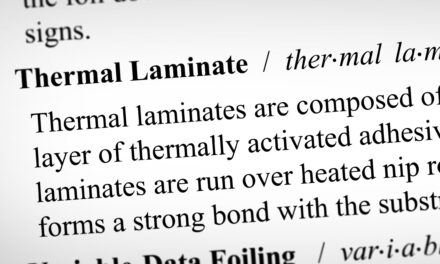

In the modern packaging space, individual portions became increasingly popular as the average consumer sought out more variety and prioritized on-the-go snacking. Seeking to draw in more customers, brands began prioritizing the printing capabilities of their packaging suppliers. Colorful cereal boxes, tactile and embellished labels, and specialized flexible packaging with unique fitments have become more widely available than ever before. Offset and flexographic printing continue to play an important role in mass production even as digital printing enables brands to target more niche markets at smaller volumes or offer customizable designs.

The print and packaging industry is truly diverse and capable of more accurately targeting the needs and tastes of specific demographics and consumer bases. Incredible advancements in printing technology have enabled brands to take more control over the way they market their products even as packaging offers greater protection. As more consumers and brands begin to prioritize sustainability, alternative materials and processes are being engineered for more eco-conscious practices.

FINISHING SOLUTIONS FOR PRINTS AND PACKAGING

Finishing solutions like those in the Nobelus portfolio now offer brands and packaging producers a vast array of value enhancements. Tactile finishes, such as soft touch, sandpaper, and linen, help brands make an instant connection with consumers. Scratch-proof and smudge-proof laminates protect packaging and other applications from being damaged during regular use, and there are even plastic-free options for brands who want to make compostable labels or flexible packaging. If you’re interested in exploring more finishes, reach out to the Nobelus team and let us learn more about your business!

CONTACT US

Resources:

- The Evolution of the Processed Foods Industry, Cablevey Conveyors. https://cablevey.com/the-evolution-of-the-processed-foods-industry/

- A History of Packaging, Ohioline. Ohio State University Extension. https://ohioline.osu.edu/factsheet/cdfs-133

- The History of Packaging, U.S. Packaging & Wrapping LLC. https://uspackagingandwrapping.com/blog/the-history-of-packaging.html

- History of Printing Timeline, American Printing History Association. https://printinghistory.org/timeline/

- Information for the Masses, Treasures of the McDonald Collection. https://scarc.library.oregonstate.edu/omeka/exhibits/show/mcdonald/printing/masses

- Unveiling the Secrets of Ancient Egyptian Ink, The Science Breaker. https://www.thesciencebreaker.org/breaks/maths-physics-chemistry/unveiling-the-secrets-of-ancient-egyptian-ink