Cleaning Your Heated Rollers

Important!! Ensure that the heated rollers have no plastic and/or adhesive on the roller! If they do, they need cleaning. It’s always easier to clean the heated rollers when they’re hot. Have a look at this article for more detail on cleaning the rollers.

Loading

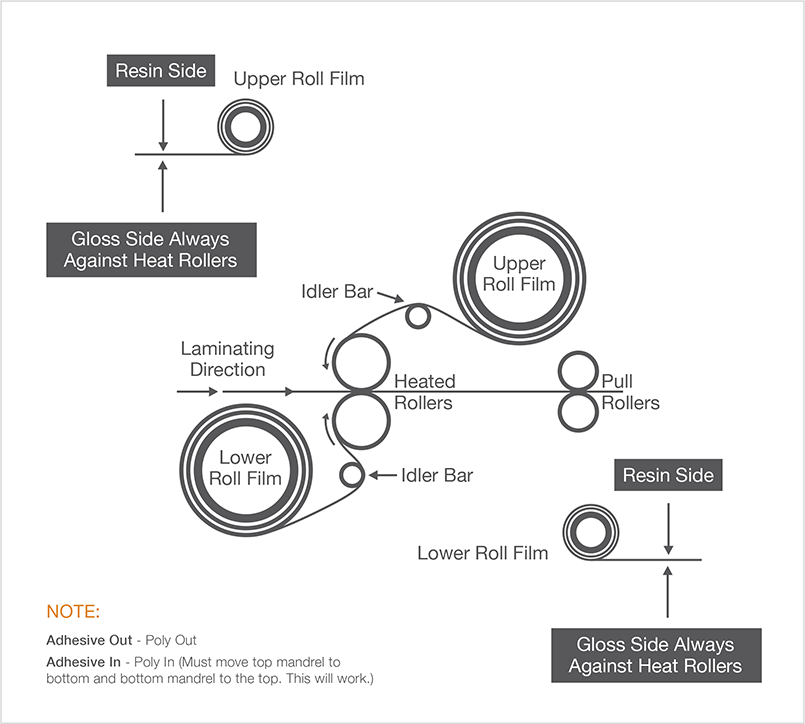

Always remember that the Glossy side should be against the heat shoe/roller. It’s easy to tell which side of the film has the adhesive on it – the Matte side of the film is the adhesive. Keep this away from the heat shoe/rollers!

Threading

Threading the film is also important. Below is a diagram that helps clarify the correct threading method. This goes hand in hand with loading the film.

If the adhesive side touches the heat shoe/roller, it will cause wrap ups, and in this case, you will need to clean the rollers before you can continue. We suggest that you always run a test sheet.

Temperature

Most films will adhere at 280 – 300°F. Ensure that you allow your laminator to properly heat up before you start to laminate. Cloudy laminate usually indicates that the temperature of the laminator is too cold. Adjust your temperature setting and wait for the laminator to heat up.

Tension

Tension is also very important and minimal tension is better. If your document is curling up, adjust the tension on the top roller. If it’s curling down, adjust the temperature on the bottom roller.

Learn more about tension adjustment in this article.