Sleeking™ Technology Significance

The technological impact of the new 4-Step Sleeking, and the Over-Printable Foiling, is significant on many fronts. Based on the original innovation of bonding a special metallic foil or spot coating (gloss, matte, or holographic), 4-Step takes this to a new level.

Market significance for equipment:

Firstly, this technology removes the most time-consuming and costly portion of the traditional foil-stamping market: dies. For several centuries, dies have been needed to properly foil-stamp mono-color foil onto a variety of substrates. They are typically expensive, require outsourcing (except for larger shops), offer little variable-data options, and must be stored.

This technology is also destroying the traditional (Kluge-style) market for foiling equipment.

The fact that Sleeking can be achieved on a specially equipped Sleeking laminator has multiple implications: it allows printers the ability to insource not only their foil stamping and spot coating, But also allows insource of their laminating needs, boosting turntimes and profit margins.

Market significance for supplies:

The market significance for foil consumables is also huge. No longer does a printer need to stock dozens of PMS foil colors. The over-printability of the special Silver Foil allows the creation of ANY color of foil that CMYK combinations can produce. This is huge, and is a significant disruptor in the industry.

Market significance for product categories:

Foil stamping is used across a wide number of industries. For the PIA, this would typically fall into any markets connected with traditional printing. 4-Step Sleeking and Over-Printable Foils can be used most places that traditional foils are used, but the most common are as follows: General Commercial Print, Labels, Folding Cartons, Rigid

Boxes, and more. Actual product categories that are showing the highest impact and potential for this technology is:

- High value foil products, including personalized holiday cards, announcement cards, greeting cards, wedding invitations, and more

- Security applications that need foil to deter counterfeiters

- Personalization on high-value books, like photobooks, corporate reports, school annuals, and journals/diaries

- Foil stamped personalization on direct mail is now showing signs of emerging, allowing high-impressional factor for donors with charitable organizations and large

- Customized foil-stamped packaging is in its infancy, and shows considerable promise for high-impact folding cartons and rigid boxes with names and variable- data applications

Simply put, the application of foil with variable data or personalization has never been easier, and is bound to create waves across an industry that has had very little change in the last century.

Sleeking Technology Innovation

Since its inception, Sleeking technology has been one of continual innovation, fueled by internal, external, and client research. To this day new methods, stocks, foils, equipment, and special effects… it is amazing where this technology will be five years from now.

The whole concept of Sleeking rests around the bonding of foil to digital ink, and later on, the bonding of digital ink to foil. Originally developed for HP Indigo, the development has required a long learning curve to arrive at this optimum “Rich Black” blend recommended by HP Indigo, as shown below:

Even so, other clients within the HP Indigo silo have created their own special blend of CMYK inks for the process, convinced that these work best on their equipment. We love this, and encourage clients to innovate this and the whole process to their best advantage.

In the last 12-18 months, our demo center and many clients have begun experimenting with toner-based devices. Clients have successfully achieved foil bond on select Xerox, Ricoh, Konica-Minolta, and Canon toner-based devices. Some work better and some are less effective.

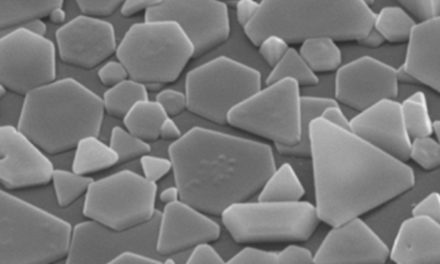

One challenge we faced early on was the “watermarking” issue, which stumped our R&D folks for months. Most digital devices are required by law to print an “anti- counterfeiting” dot pattern, in yellow, which is undetectable to the human eye. These dots, incredibly small, nevertheless would bond to the foil in the Sleeking process, creating a “speckled” look in early trials and with many customer tests. We resolved this by running toner based devices in 100% black/white toner mode only.

Another challenge that has continued, but which has been easier to innovate, is the use of different types of stock. Initially, as Sleeking required the presence of Indigo ink

on the top of a sheet, coated or finely calendared matte stocks only worked. However, more and more stocks have been able to be utilized, as it was discovered that “stacking” ink on an Indigo would provide a stable enough base to bond to the digital inks.

Other challenges have included the way foil is applied, spreader rollers and re-wind rollers, heat and pressure variations, and much more. We also continue to innovate more types of Printable Laminates to which Sleeking foil will bond to, to create even more tactile experiences.

It has been an amazing journey, and not a boring one, as we continue to lead the way in revolutionizing the way that foil is applied, how it can be colorized with ink, and the amazing effects that can be created on print, packaging, and books…more to come!