MAKING THERMAL POUCHES BETTER THAN EVER BEFORE

Digital flex pack converters know it can be hard to make tight deadlines and prioritize speed to market when material changeovers cost them hours of press uptime a day. Add frustrating quality issues to the equation, and it can feel near impossible to keep pace with demand without sacrificing in other areas.

Fortunately, Nobelus is offering thermal converters an innovative yet simple solution that will enable them to offer thermal pouches with greater efficiency than ever before. The newly launched StrataFlex™ Thermal Pre-Lam line is a direct answer to many of the challenges convertors who thermally laminate pouches face every day.

What Are StrataFlex Thermal Pre-Lams for Thermal Pouches?

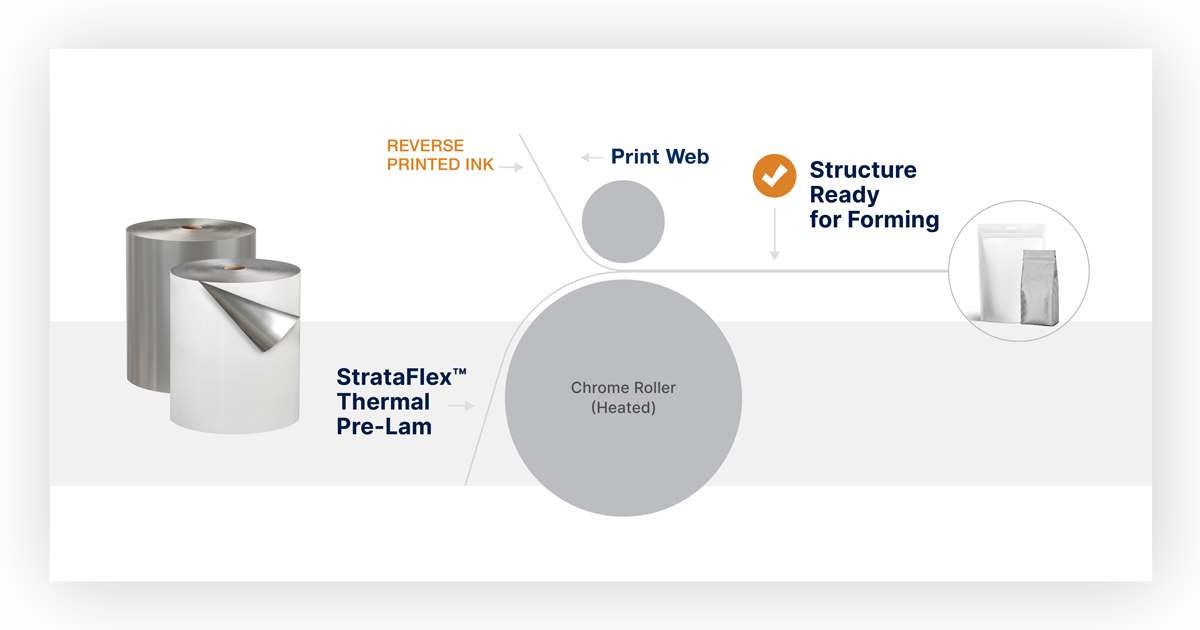

StrataFlex Thermal Pre-Lams are METPET pre-lams that offer moisture and oxygen barrier properties to support stand-up pouches, square-bottom bags, and other thermal pouch formats. These films differ from standard pre-lams in that they include an EVA adhesive layer, enabling digital converters to reverse print on an adhesive-free print web film and then thermally laminate the layers together.

When converters stop surface printing on pre-lams and swap to reverse printing, it leads to more press uptime per day as thinner film rolls require far fewer changeovers than pre-lam rolls. For many digital converters, this leads to hours more press runtime a day as material changeovers can be drastically decreased. Through reverse printing, converters can greatly increase capacity for each press, enabling them to take on more customers and reliably deliver orders on time. It also helps reduce the amount of labor needed for each press, freeing up operators to attend to other tasks.

Reverse printing simplifies the print surface due to thinner films made of a single material type. Whereas surface printing on pre-lams can lead to many types of quality issues, reverse printing minimizes these occurrences, which means less downtime while operators troubleshoot the problem. Thermal converters who gain experience with reverse printing place also themselves in a better position to grow their business if they decide to expand into solventless lamination in the future.

How to Laminate Thermal Pouches With StrataFlex Pre-Lams

Perhaps the best thing about StrataFlex Thermal Pre-Lams is that they fit perfectly into the workflow thermal converters already use. Simply swap out the print surface and then laminate the layers together using your existing equipment to create the perfect thermal pouch.

Thermal converters who have already made the swap find that, after a short adjustment period, the benefits of reverse printing become more pronounced with time as they are able to significantly increase productivity, reach more brands than before, and gain mastery over a skill that is crucial for long-term growth in the flexible packaging market.

Want to Explore Other Structures for Thermal Pouches?

Nobelus offers every layer a flex pack converter needs to thermally laminate pouches, from our wide range of print web films to our thermal pre-lams and PE thermal sealants, which also support recyclable applications. Visit our flexible packaging solutions page to learn more or schedule a consult with one of our in-house solutions experts. With years of experience in flexible packaging, our solutions specialists are able to provide insights on workflow optimization, food safety, application engineering, and much more.