A Complete Glossary, Part II: Equipment

Laminating systems are available in a huge variety of designs, sizes, and volume capabilities, so it should come as no surprise that the terminology surrounding these machines is equally varied and complex. From the largest units to the smallest components, Nobelus® knows laminators inside and out. Read through our glossary of equipment terms to make sure you are up to speed on different laminating systems and how they operate.

Equipment Terms From A to Z

TIP: To locate a term quickly, press ctrl and F simultaneously and then type the term in the search bar that appears.

AIR-SHAFT MANDREL

This device uses compressed air to lock film rolls in place during the lamination process to prevent quality issues or damage to the laminator. An air-shaft mandrel makes changing out film rolls quick and easy compared to other types of mandrels that require manual tightening.

ANTI-STATIC UNIT

Because static electricity can cause issues with feeding and stacking in the lamination process, anti-static units produce ions to reduce or eliminate static electricity at the source.

BACK ROLLER

Also called pull rollers, back rollers pull finished sheets out of a laminator so they can be stacked.

BOTTOM MANDREL

This is a shaft that is typically mounted below the feed table on a two-sided laminator to hold the film roll in place as laminate is pulled through the laminator.

BOTTOM-FED LAMINATOR

Bottom-fed laminators pull sheets from the bottom of a stack. This feeding method enables operators to add sheets to the stack as needed while the laminator is running, making it perfect for on-demand or short-run production volumes.

BURST ROLLERS

Burst rollers are used on laminators that employ bursting separation. They get their name from the way they use a quick burst of speed to pull apart laminated sheets.

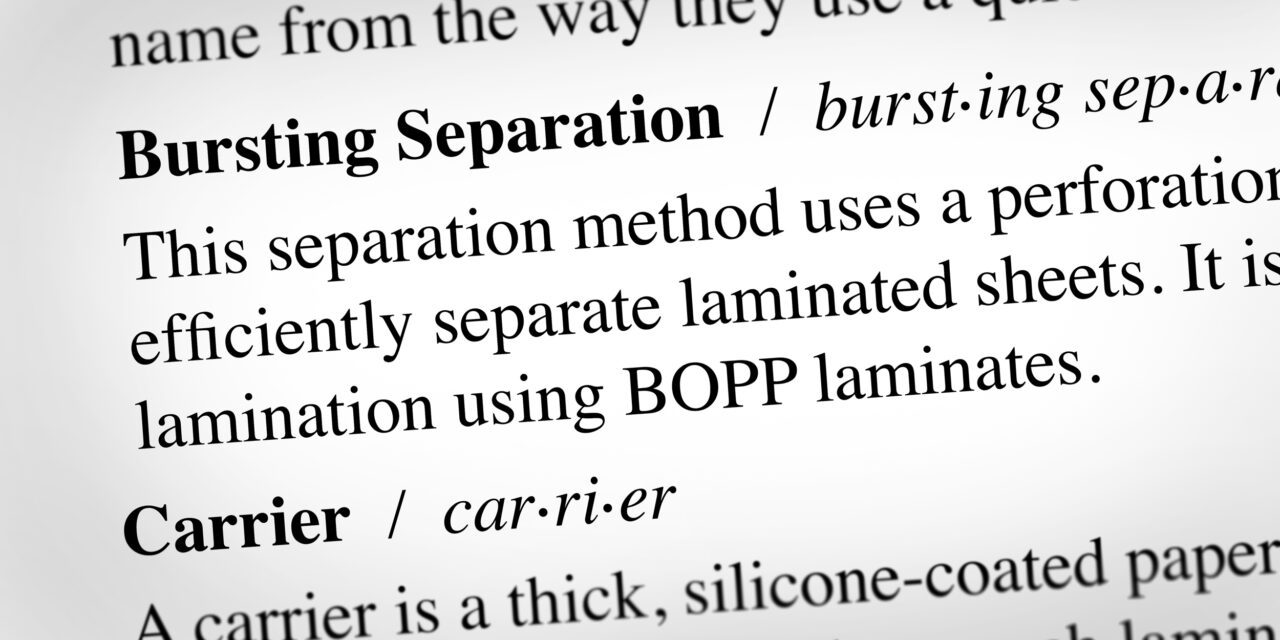

BURSTING SEPARATION

This separation method uses a perforation tool and burst rollers to quickly and efficiently separate laminated sheets. It is most suitable for use with single-sided lamination using BOPP laminates.

Learn more: 5 Common Separation Methods for Different Types of Lamination

CARRIER

A carrier is a thick, silicone-coated paper pouch that is folded on one side, enabling pouches to be fed through a pouch laminator without excess glue making contact with the rollers.

CHILLER SYSTEM

Typically used only on high-speed laminating systems, chiller systems use chilled water to cool the laminated web after the laminating process is complete. Most SHR machines require a chiller system.

Learn more: What Equipment Do I Need for SHR?

CONTROL PANEL

The control panel on a laminator enables the operator to set up and make adjustments to the machine as needed. Most modern control panels use touchscreen technology and intuitive user interface. This panel can also be called a human machine interface (HMI).

COOLING FANS

Located between the nip and pull rollers on most two-sided laminators, cooling fans provide forced air to cool film quickly and prevent curling issues.

COOLING TRAY

This flat surface at the rear of a pouch laminator enables pouches to remain flat after they are laminated and cool down without warping.

DANCER BAR

This feeding technology is used on high-output automatic trimmers and gets its name from the way it moves swiftly up and down to help laminated sheets flow smoothly into the trimmer.

DE-CURLING BAR

Because the lamination process can often create a natural curling effect in laminated sheets, a de-curling bar provides a way to counteract this effect. The bar is typically used in single-sided lamination to “break” the fibers in a sheet, reducing the pull of the film layer and enabling the sheet to lie flat.

DE-CURLING ROLLER

Much like a de-curling bar, a de-curling roller is used in single-sided lamination to reduce or eliminate the natural tendency of sheets to curl when a thicker sheet begins to cool.

DEEP-PILE FEEDER

A deep-pile feeder is a top-running feeder that accepts deep stacks of sheets to reduce the frequency with which operators have to load sheets and minimizes interruptions in the workflow. This feeder is best suited for large-volume runs of identical jobs.

DOUBLE-SIDED LAMINATOR

Double-sided laminators are capable of laminating both sides of a substrate in a single pass through the machine. Some units laminate both sides simultaneously, while others will laminate the top first and then the bottom. Both types require two film rolls to be loaded.

DUAL TEMPERATURE CONTROL

Common on smaller laminators, dual temperature controls are capable of adjusting temperature settings on the top and bottom rollers or heat shoes simultaneously to accommodate different material types.

ELECTRIC REVERSE

When a laminate begins to jam or experience any other unwinding issue, an electric reverse enables the operator to run the machine in reverse and locate the point on the web where the issue has occurred.

EMBOSSING ROLLER

Specially textured embossing rollers are used to give laminates with a gloss finish a photo luster. These rollers can be found on laminating systems designed to perform silver halide replacement (SHR™) as they can be combined with SHR Laminate to perfectly recreate the appeal of traditional silver halide on digital photo prints.

Learn more: What Equipment Do I Need for SHR?

FEED GUIDE

This small edge guide is located on the feed tray of a hand-fed laminator and enables prints to be fed into the laminating system at the correct angle.

FEED TABLE

A feed table holds stacks of paper within reach of the laminating system’s nip rollers. They can operate using a variety of methods and hold different sized stacks to support a range of production volumes.

FILM SLITTING UNIT

On some laminating units, a small, sharp cutting wheel is attached to the laminate feed mandrel, enabling in-line slitting of laminates to a desired width before the web enters the laminating machine.

FLYING KNIFE SEPARATION

A flying knife separation mechanism draws a knife quickly back and forth across the laminator to separate laminated sheets. This blade can slice through a wide variety of laminate material types, including BOPP, PET, nylon, and cellulose.

Learn more: 5 Common Separation Methods for Different Types of Lamination

FLYING ROTARY KNIFE SEPARATION

A flying rotary knife separates one laminated sheet from another by rolling a circular metal blade across the width of the web. It is compatible with double-sided lamination and most common laminate materials.

Learn more: 5 Common Separation Methods for Different Types of Lamination

FRONT ROLLERS

Sometimes called feed or nip rollers, these are the first two rollers in a laminator. They pull unlaminated sheets into the machine to begin the lamination process.

GUILLOTINE SEPARATION

A guillotine knife slices downwards to cleanly separate sheets. This method is strong enough to be used in double-sided lamination.

Learn more: 5 Common Separation Methods for Different Types of Lamination

HEAT SHIELD

Heat shields prevent an operator’s fingers from being burned by heat shoes or heated rollers while they feed prints into a laminator.

HEAT SHOE

Thermal laminates include a heat-activated adhesive layer, and heat shoes provide the necessary heat to soften and prepare this adhesive for application before the laminate reaches the nip rollers. These devices are stationary and require laminates to be pulled across their surface.

HEATED ROLLER

These laminating rollers are usually made of chrome or rubber and contain a heating element. Heated rollers are similar to heat shoes, but they roll with the laminate as it passes through and provide more direct heat during application. Because they typically provide a stronger bond than heat shoes, these rollers are popular in applications that use challenging digital inks.

HOT KNIFE SEPARATION

Unlike other separation methods, a hot knife uses heat to melt and vaporize the laminate gap between laminated sheets, leaving extremely clean edges. While it can cut through BOPP, PET, nylon, and cellulose laminates, it limits the materials that can be used for substrates and embellishments.

Learn more: 5 Common Separation Methods for Different Types of Lamination

IDLER BAR

An idler bar, also known as a spreader roller, is a small bar or roller that laminate passes over or under immediately after it is pulled off the film mandrel to keep it taut. This component helps laminates flow smoothly into the unit’s rollers without twisting or becoming wrinkled.

JOGGING TABLE

This vibrating stacker or catch unit is used on the back of laminating system to keep sheets evenly stacked and flowing freely.

LAMINATING PRESSURE ADJUSTMENT

Found on most laminators, this device uses a lever or pneumatic adjustment to enable operators to set pressure for the nip and pull rollers during the laminating process.

LAMINATOR

Laminators are large, complex pieces of equipment that use pressure and oftentimes heat to combine substrates and laminates in an efficient, cost-effective manner. They come in a variety of capabilities in terms of operation, volume, and compatible material types.

NIP ROLLER

Sometimes referred to as “pinch rollers” or “laminating rollers,” nip rollers help guide substrates and laminates throughout the laminating process and press the webs together to create a strong bond. Nip rollers can be adjusted to accommodate different materials and thicknesses and may be heated to ensure thermal adhesives are the correct temperature as the laminate is applied to the substrate. They can be made of chrome, silicone, polyurethane, and a variety of other materials.

PERFORATOR

Laminators that utilize bursting separation will typically include a special wheel that punches tiny holes along the edge of the laminate, weakening the laminate connecting each sheet. This wheel is called a perforator and enables laminated sheets to be skewed and burst apart.

PLATENS

These large metal plates serve as a heat source for pouch laminators.

SEPARATOR

Also called a bursting or snapping unit, this device is included on most one-sided laminators and quickly pulls or “bursts” sheets apart as they exit the laminator.

SINGLE-SIDED LAMINATOR

These units are capable of laminating only the top of a substrate in one passthrough. Laminating the opposite side of the piece will require the sheet to be passed back through the machine with the unlaminated side facing upwards.

SKEWING WHEEL

This small wheel is used to angle sheets slightly during the bursting process, enabling the perforated edge to tear and cleanly separate one laminated sheet from the next.

SLEEKING™ MODULE

This optional feature takes up the liner and excess foil from a roll of Sleeking foil after it is used to perform variable-data foiling. Sleeking modules can be attached to a variety of laminating systems in the field.

Learn more: What Is Sleeking?

SLITTER KNIVES

Positioned between the nip and pull rollers on double-sided laminators, these cutting devices trim the sides of the laminate automatically before the laminated web exits the machine.

SPRING-HINGED ROLLERS

Spring-hinged rollers in a pouch laminator support various thicknesses and are often used on machines that can perform lamination and mounting on board simultaneously.

STACKER

Larger laminating systems use stackers to neatly hold finish laminated pieces when they leave the laminator. This enables laminated sheets to be fed directly into other post-laminate processes.

TAKE-UP MANDREL

An additional mandrel that is typically mounted on top of a laminator, the take-up mandrel rolls up materials such as release liners or Sleeking foils after application.

THREADING CARD | THREADING BOARD

This piece of thick board or cardstock is used to thread laminate through nip and pull rollers in a safe manner.

TOP-FED LAMINATOR

Top-fed laminators draw from the top sheet in a stack. Because this method does not allow more sheets to be added, these systems are best suited for production-volume runs.

UPPER MANDREL

A crucial laminator component, the upper mandrel is a shaft mounted above the web path that holds the laminate roll as it is unwound.